You may have heard of the term ‘work order’ pretty often but what does it entail necessary?

A work order is a basic tool for communication within any organization. It communicates everything regarding a task or job to be done. It starts with what the task is to who will do it and how.

Work orders are created when either the customer or the company feels like there is a need to track the progress of a particular task.

They provide companies with vital information on employee productivity and ensure that all business tasks are executed in an efficient manner. A work order also irons out the workflows of a company.

With all the necessary information already available within a work order, there is less time lost gathering information from scratch. Managing different operations is also easier with a work order.

How can you use a work order for maintenance management?

Work orders can be used for different purposes. A work order comes in handy whenever a task needs to be done. Using work orders for maintenance management is one such important use case.

Maintenance work orders have to do with creating requests for scheduling maintenance services for equipment or parts.

You may be wondering, why do we even need a maintenance work order at all? The answer is simple – for seamless maintenance management.

Without using work orders, there are no clear instructions on how to go about solving the problem at hand. This ultimately bleeds into errors and inconsistencies.

A maintenance work order may include one or more of the following basic information:

- Who is requesting the task?

- What is it about?

- Who is authorizing the task?

- When is the task to be completed?

- Who is the assignee?

- What is the priority level?

- Any additional instructions and costs details

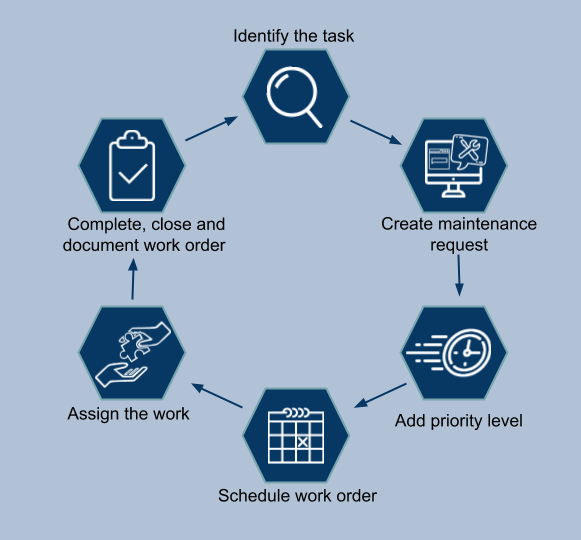

Maintenance Work Order workflow

Every maintenance work order follows a standard workflow. Here’s what each of its steps entails:

Step 1: Identifying the task

Every work order starts with the identification of what the task is about. The maintenance task may be of two types: planned or unplanned.

Planned maintenance includes scheduling maintenance sessions beforehand to prevent any future equipment breakdowns. For example, the routine inspection of any tool falls under planned maintenance.

As opposed to this, unplanned maintenance includes problems that you can’t know of before time. This includes instances such as an unexpected breakdown of equipment.

Step 2: Creating a maintenance request

Once the task is known, it is time to create a maintenance request for it. This formally begins the maintenance process.

The request includes all the information about the task, along with further details such as the due date.

Step 3: Adding a priority level

Priority levels are important to ensure that the task is dealt with in a timely manner. If the task is a time-sensitive one, then you want to choose the highest priority level available.

However, make sure that you don’t assign every single task the highest priority. This will cause delays in the resolution of important tasks, ultimately costing the company.

Step 4: Scheduling

Next, you need to schedule the work order based on when you want to complete it. If you have a set deadline in mind, then you can schedule the work order according to that deadline.

For planned maintenance, you can schedule the task beforehand and it will be initiated at the specified time.

Step 5: Assigning

To examine the progress of any work order through to its completion, you obviously need to assign it to someone. Remember that a work order cannot begin before you assign a technician to it

When assigning, make sure that the technician chosen is available throughout the entire work order process and doesn’t have prior commitments.

If that is the case, then the technician will have to leave midway, leaving the task incomplete.

Step 6: Completion, closing, and documentation

This is where all the information in a work order starts transforming into action to complete the maintenance process. Once all the work is done, you can close the work order request.

The closing of a work order may require a manager to sign off on it after checking that everything has been done as instructed.

Lastly, you should maintain a well-documented log of the work order. This shall prove useful in the future.

Advantages of implementing Maintenance Work Orders

Work orders allow you greater control over the maintenance processes. Moreover, assigning a work order to the relevant member allows you to track and optimize their performance.

If that doesn’t convince you about the need for maintenance work orders, then here are more reasons to opt for them:

1. They provide important information?

A work order tells you much, ranging from the particular task at hand to the entire standard maintenance processes involved.

If you aim to properly document a work order, you must store detailed information every time a problem or service task arises.

This information then helps solve problems quicker the next time a similar or identical problem arises. You can use this to your advantage to improve work efficiency.

Moreover, it can even help you decrease the frequency of recurring problems as well. By studying this data, you can find the root cause of each equipment breakdown instance and thereby devise a solution.

Furthermore, if an issue keeps arising often, it hints at something faulty in the entire maintenance process.

In such instances, the documented information becomes vital. It helps you analyze and understand where the process might be flawed.

There may be instances in which the first solution fails. The task may remain incomplete, with time running out.

In such situations, a detailed work log can help the technicians figure out alternate solutions, learning from mistakes in the first one.

2. They help organize and prioritize

Without a work order, employees create maintenance requests informally, with no documentation or proof. This leads to inefficiencies, confusion about who is to do what, and which task is the most important.

A work order helps deal with such inefficiencies by forming a formal model to create, assign and complete task requests.

As a company, you want to ensure that the most important tasks are dealt with urgently. A maintenance work order specifying the priority level of a task can make that happen.

However, if your business doesn’t use work orders, then priority tasks won’t be dealt with in a timely manner. This could lead to major costs as a result of time lost and equipment unavailable for too long.

3. They improve work efficiency

A work order provides information that ensures one thing – every employee is on the same page. Everyone knows who the technician on the task is, what the issue is, and when is the deadline.

This means that there is no miscommunication and everyone is clear on the role they play. Consequently, this translates into fewer mistakes, and less time fixing errors or clearing confusions.

A maintenance work order system also provides a standardized process. This improves clarity and quality since work is done in a pre-defined and optimized way.

All this fuses to one huge benefit – improvement of work efficiency.

Read More: 3 Benefits of Managing work orders with Relevant Software

Best practices for Maintenance Work Orders

Here are some best practices regarding work orders that will help you in implementing maintenance management for your company:

1. Every task must begin with a work order request

It seems like a given that every task will, of course, begin only with a work order request.

However, though it may sound rudimentary, you’ll find it shocking how often team members try bypassing the work order request process.

It’s human nature for all of us to want to get our work done ahead of time without the hassle of formally filing a request. That is exactly what you want to discourage your employees from doing.

For this reason, you must make it clear from the start that all employees are to follow a standardized procedure. Having a standardized process helps improve the reliability and quality of your maintenance tasks.

Make sure that you do not accommodate any task request unless it comes through the formal work order request pipeline.

No matter what the task may be, everything must go through a standardized initiation process, whether it’s a light bulb or a conveyor belt breaking down.

2. Remember to select the correct assignee

Choosing the right assignee is an integral part of the work order process.

Failure to choose the right technician might delay the availability of equipment even further. Or it may lead to even bigger problems than the initial one that needed fixing.

There are many important questions for you to ask when selecting the assignee. Some of these include “How many people does the task require?” or “Why should I choose this particular technician?”

Another significant thing to consider in choosing the correct assignee is whether you require an outside contractor or not.

Maybe the task might be too much and your technicians might not be adept at handling it. Or maybe you just don’t have the manpower needed available at the moment.

In such moments, an outside contractor to assign the task might become necessary.

3. Provide access to appropriate resources

If you’ve been collecting a work order log for a while, then you must have a sufficient information base by now. Make sure to share this information base with the assignee to help them in their work.

Similarly, if any other resources can help complete the maintenance work order more efficiently, then make sure to provide those too.

The resources can be of any sort, such as asset history reports, videos, diagrams, and even purchase orders. This additional help makes the whole process quicker, thereby ensuring the timely return of the equipment.

A most helpful resource would be past notes that the previous technician might have made about the equipment in question.

This is especially useful when dealing with unique pieces of equipment which aren’t to be dealt with the same way as all others.

Notes from fellow technicians can reveal useful insights to help improve the maintenance process.

4. Replace pen and paper with a competent software

44% of companies are still using paper records for their maintenance reports. There are many reasons for why that is.

Pen and paper may seem simpler and more cost-effective. It may even be the way you’re used to doing things, so why change. There aren’t any associated training costs either.

You might think pen and paper are saving you from huge material costs. However, in reality, they’re costing you far more.

Pen and paper is an inefficient system. Paper files often get lost or damaged, leading to loss of useful information. Writing down everything by hand also results in inaccurate information and slower response time.

This leads to loss of valuable time that could be better spent elsewhere, such as focusing on the core strengths of the company.

Shifting from the outdated pen and paper to relevant maintenance work order software offers companies many benefits.

It makes work orders easier to create and track. Moreover, such software also helps increase efficiency. There’s improved response time, and next to no loss of any important information.

5. Determine a set of rules for prioritization

You need to define what sort of maintenance falls under high priority and what sort falls under low priority.

If you don’t determine a standardized set of rules for prioritization, then the maintenance work orders will be dealt with inconsistently.

For example, a fused light bulb doesn’t fall under “Urgent” on the priority levels. However, some members might file it under the highest priority because it is something that they feel needs to be dealt with urgently.

To avoid situations like these, develop a rubric that is easily understandable by all. This will help ensure that you deal with the most important tasks first and only then move on to the routine task requests.

Time to put these best practices to us

A maintenance work order can help improve your company’s work efficiency and offers many other advantages as well.

Don’t forget to choose the correct assignee and make sure you always provide any useful resources available.

Stick to a standardized process for initiating maintenance requests and assigning priority levels. This will help decrease ambiguity and errors.

Lastly, consider shifting your paper-based maintenance records to the software system for greater productivity.

To truly benefit from work orders, remember to stick to these best practices mentioned above in this article.

About EZO CMMS

EZO CMMS is the next generation maintenance management software. It does more than just simple maintenance, it empowers your teams with a central command center to assign and complete work orders to achieve optimal productivity.