This article will take you through machine downtime tracking, its costs to an organization, and some best practices that can be utilized to pave the way for efficient maintenance processes.

Downtime is generally defined as a period in which a piece of equipment is non-functional and does not produce any useful output. All equipment, large and small, can suffer from downtime. This may include IT assets like laptops and printers, as well as heavy industry machines such as turbines and pumps. Power outages, unplanned maintenance, or the shortage of materials or staff can all contribute to equipment downtime.

Downtimes are expensive business. They cost the world’s top companies billions in revenue every year. A recent report claims that businesses lose $84,000 to $108,000 USD for every hour of IT system downtime. This is why it is extremely important to understand what disrupts machine uptime. It can help you improve lean operational processes, and lower costs in the long run.

Causes of Equipment Downtime

Every minute a machine isn’t running as expected at your company, there is a chance of lost revenue. It is important to know the causes of equipment downtime before we can move forward and look for remedies. Listed below are some of the major causes of equipment downtime:

- Irregular maintenance: Most equipment requires regular preventive maintenance for consistent performance. Preventive maintenance refers to regular maintenance events that are undertaken to keep machines working at optimal levels. Worryingly, it is common practice to brush off preventive maintenance when the equipment seems to be working fine. Failure to deploy routine preventive maintenance techniques makes machines more prone to breakdowns.

- Failure to monitor the equipment lifecycle: Monitoring the equipment lifecycle makes it easier to keep track of equipment depreciation, and helps make more accurate predictions of when an equipment needs maintenance services. Keeping track of equipment from deployment to retirement helps pinpoint maintenance needs and make sure the equipment keeps working at maximum efficiency till its retirement.

- Overrunning machines: Constantly pushing machines to run at maximum performance or at the top of the engineering curve can strain joints and cause equipment to die prematurely. Overrunning machines beyond their capabilities and without proper maintenance makes them prone to costly breakdowns.

Calculating Upfront Equipment Downtime Costs

While the causes of equipment downtime can be easily listed, it isn’t always easy to quantify the cost incurred due to it. According to estimates, 80% of industrial facilities were unable to accurately cost downtime.

Before the overall downtime cost for a company’s equipment can be calculated, you need cost calculations for the following:

- Direct labor costs: To calculate this, take the length of downtime and multiply it by the hourly rate of the machine operators.

- Indirect labor cost: You can calculate this by determining the overall share of crew workload the machine takes, and then multiplying that by the costs of the support staff and managers.

- Product cost: This is equal to the value of the product that would have been produced during the downtime, minus the costs of the material used in the production.

- Start-up cost: This is the cost incurred when restarting a particular equipment. This includes energy surges and any additional workers needed for the action.

The total downtime cost for a particular machine is then calculated by adding all the above expenses.

Machine breakdowns can cost businesses a lot of resources both in terms of time and money. An accurate calculation of these costs can allow managers to make decisions as to when to plan equipment downtimes, or in the case of repairs, how much to spend on getting the machine running again.

The Hidden Costs of Equipment Downtime

Not all costs of equipment downtime can be easily calculated. According to research, the average manufacturer deals with 800 hours of downtime per year. Just for perspective, consider that the average automotive manufacturer loses $22,000 per minute of downtime. This can include a lot of hidden costs too. A breakdown of the more obscure financial effects of equipment downtime are as follows:

- Idle labor: For the period the equipment is unavailable for use owing to downtime, the employees you’re paying to operate the equipment essentially become useless. This cost of labor rendered idle by the unavailability of machinery is known as wasted labor cost.

- Production loss: Downtime directly affects daily production which can incur huge losses. As an example, if a manufacturing facility produces 500 units every hour with an average profit of $20 per unit, the direct cost of production loss due to equipment downtime for an hour comes to a staggering $10,000.

- Legal penalties: A business may face serious consequences if it is unable to meet its targets. As an example, a company that had promised a certain amount of product to a consumer might be hit with legal penalties for not delivering on specific Service Level Agreements.

- Dissatisfied customers: The other aspect of not delivering on your promises is that you risk losing credibility and trustworthiness among your customers. Downtime prevents you from reaching operational goals and meeting customer demands. This results in loss of sales and customers, and hence money.

How Can Asset Tracking Help?

When companies don’t put much thought into maintenance management, the financial costs of equipment downtime can really pile up. The good news is that these costs can be lowered just by deciding on and executing better equipment maintenance workflows. Asset tracking software can help a great deal in this. Below, we mention some of the main features present in an equipment management software that can help companies implement improved machine downtime tracking:

- Maintenance life cycle tracking: These help monitor regular checkpoints in the asset life cycle. This can be important in figuring out which items are being maintained more than necessary, and which are costing the company the most money to maintain. This kind of data, gathered using an equipment maintenance log, can help companies reduce equipment and personnel downtime.

- Service tickets: You can generate service tickets for both routine repairs as well as one-off breakdowns. For example, you can set up repeating service cycles for regularly services assets, and can also flag up malfunction assets to ensure speedy repair and substitution. This prevents large scale issues that often result in huge costs.

- In-depth reports: Reports can be generated to help you analyze breakdown patterns. Knowing the vulnerabilities and repair frequency of your assets can help you make informed purchasing decisions and improve overall efficiency.

- Audits: Maintenance managers can carry out regular audits to gain timely insights into the health and status of their equipment, helping prevent costly breakdowns. The results of these can be shared with key stakeholders on the cloud. This can have huge benefits for your company, as future decisions are made based on accurate real-time data.

- Mobile apps: These allow managers to access asset information from any device, at any place, and at any time. This enables them to manage the calibration and maintenance schedules of equipment on the go. Immediate actions prevent wait times and delays in getting equipment fixed, which can save you costs lower down the line.

Best Practices for Machine Downtime Tracking

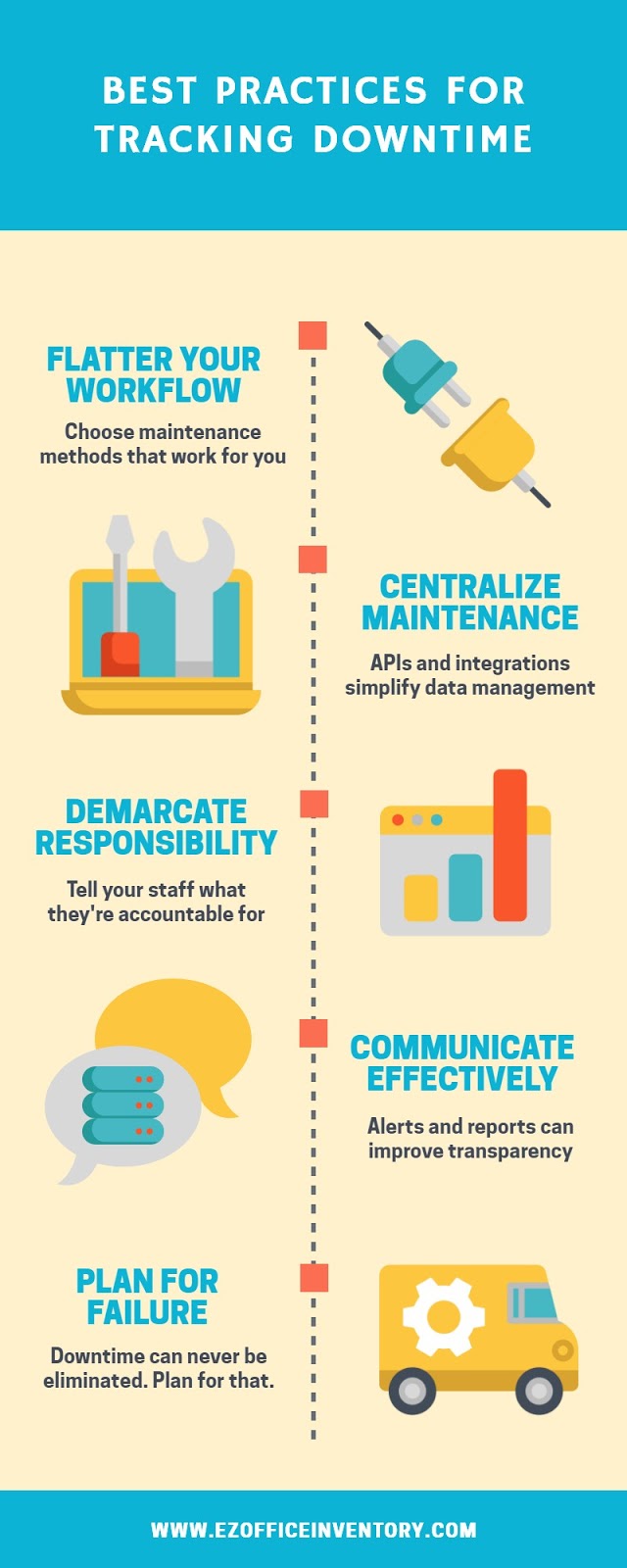

There are a lot of ways to ensure you excel at machine downtime tracking. Below, we’ve put together a list of best practices that, when implemented, can give you the push you need to execute flawless maintenance operations.

- Pick a method that suits your workflow: Identify your requirements and choose the maintenance method accordingly. Preventive maintenance is triggered by time. It is most efficient when you wish to deploy planned maintenance events at regular intervals. You can use this preventive maintenance checklist to learn about getting the most out of routine services at your organization. In contrast, predictive maintenance is based on the actual condition of the asset. It is generally used to predict machine failures before they occur and allows you to schedule a future service appointment in advance. It is therefore important to analyze your needs before you invest in a maintenance infrastructure for your assets.

- Centralize your maintenance process: Collecting your maintenance data in one single space can help streamline your maintenance processes. This is because a centralized information base simplifies your workflows and reduces processing time. You can use APIs or integrations to gather all your maintenance data in one place. As an example, an integration between Zendesk and asset tracking software can allow you to deploy service tickets and view asset maintenance histories from the same space.

- Demarcate responsibilities clearly: It is important that maintenance managers clearly delineate the maintenance responsibilities of each individual or department. This ensures that there is no overlap, and helps create a sense of accountability amongst your employees. For example, if the maintenance of HVAC structures is the responsibility of the maintenance crew, and the license renewal of laptops is the responsibility of the IT department, communicating these tasks to the relevant departments ensures that neither laptops not HVAC structures are in an accountability grey-zone.

- Communicate expectations and results: In addition to delineating employee responsibilities, it is important that each stakeholder in the maintenance process has some idea about the larger picture. Increased transparency shows everyone the capacity within which they are working towards a larger goal. Alerts help you identify which kind of services are needed before you need them. This gives you ample time to make sure you have all the tools, crew capacity, and materials before you go into a maintenance project. Additionally, sharing equipment maintenance record keeping can help motivate employees, and gently nudge them in the right direction if things are going south.

- Plan for worst-case scenarios: Of course, the purpose of this post is to equip you with the knowledge you need to minimize downtime. However, while downtime can be lowered to a great deal with smart planning and robust processes, it is not something that can be entirely eliminated. This is why you must plan for downtime effectively, and even factor in worst-case scenarios so you’re never caught by surprise. For instance, you must communicate downtime periods to employees effectively. In addition, make sure to schedule downtime periods at intervals that are least obstructive for your employees and do not take up productive work hours. In-depth reports can really help to provide you with these kinds of insights.

Conclusion

Machine downtime tracking is valuable for many reasons. For starters, the statistical analysis, reporting, and charting of downtime history reveals important maintenance trends. These trends can help managers employ preventive maintenance techniques and prioritize and implement corrective action as needed. This increases equipment longevity and enhances operational efficiency. The U.S. Department of Energy estimates that preventive maintenance techniques can help reduce energy and maintenance costs by 30%, reduce machine breakdowns by 35%, and reduce downtime by around 75%. All of this not only increases workplace productivity, but also saves labor and replacement costs.

Managing downtimes remains a challenge for businesses, both small and large. A computerized maintenance management system can make this task a lot easier. Taking care of your equipment with regular maintenance actions extends the usable life of your machinery, ultimately giving you more use for every dollar. It also helps identify early maintenance needs and deploy inexpensive solutions, saving you from dealing with major, costly breakdowns later on. All in all, machine downtime tracking software is a valuable addition to any organization.

About Maintenance Software

EZO CMMS is a leading equipment maintenance software used by companies around the world. Use our solution for optimized maintenance workflows, accurate machine downtime tracking, and more.